(Excerpt from an article in "Beschaffung aktuell"):

Relevant selection criteria for industrial PCs

The brain factor industrial PC

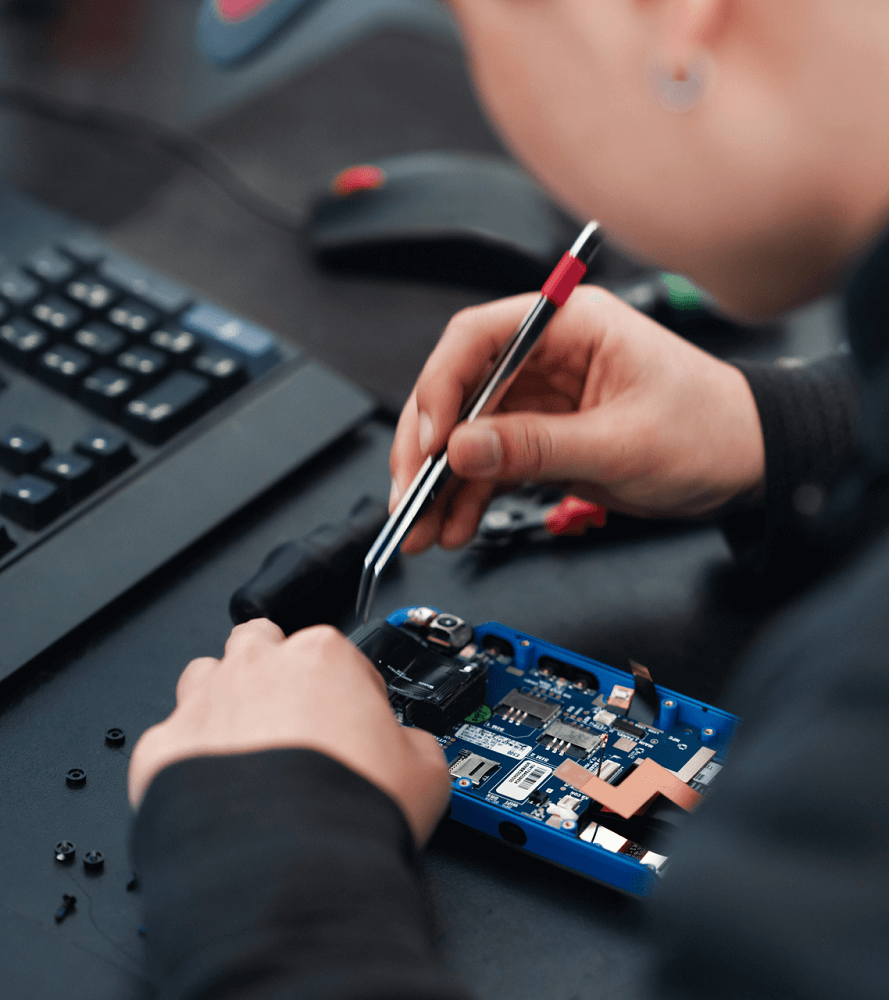

Digitalisation, automation and networking are creating a growing demand for industrial PCs. However, the short innovation cycles of the various PC components exceed the useful life of industrial IT hardware many times over. An overview by industrial IT experts is intended to assist in the selection process.The industrial PC (IPC) represents the basic foundation for the growing networking of distributed devices. In short: the industrial PC is becoming the brain factor. The demands on industrial IT and its performance are increasing - whether the company is small, medium-sized or large. "Because every detail counts for industrial PC systems, the technical features depend on the extended functionalities for the respective area of application," Stefan Götz, managing partner of TL Electronic from Bergkirchen near Munich, knows from almost four decades of industrial PC experience. Added to this are the many customisation options. Sometimes even small mechanical changes make an enormous difference. The application-specific solution is an exactly fitting choice of industrially suitable and long-term available components based on quasi-standards. In essence, three main criteria are decisive for the professional procurement of industrial PCs: technology, costs and service logistics. "When it comes to hardware configuration, you can largely fall back on off-the-shelf components. Nevertheless, I recommend a 360° view for the most economical and technically best IPC solution for the selection process," says expert Götz.

Technical criteria

The area of application of the industrial PC determines the design and technical equipment for optimum performance. "That's why you first discuss the requirements and the environmental conditions that are decisive for the design and versions of the industrial PC hardware," says Götz. Whether 19-inch rack, embedded or wall-mountable box variants or a panel PC are to be used is clarified in the needs analysis. The technical equipment features are divided into:

- Design and size

- Processor performance

- Size of the main memory (RAM)

- Fixed storage media such as solid state drive (SSD)

- Operating system such as Windows 10 IoT or Ubuntu 16.04

- Number and type of interfaces and connectivity

- Number and type of slots

- Level of protection

- Display diagonal and operability for panel PCs

IPCs in the classic 19-inch format, such as the ClassicLine CL4501 series from TL Electronic, are real workhorses with high reliability, e.g. in series production. This is ensured by the Intel processors of the 9th Core-i generation Coffee Lake-S with up to eight computer cores and a clock frequency of up to 3 GHz. Another special feature of the CL series is its diverse connectivity. Eight USB interfaces, two of which conform to the fast 3.1 specification, two serial COM interfaces, two RJ45 for Gigabit Ethernet, two PS/2, audio I/O, an internal parallel port as well as DVI (Digital Visual Interface) and two display ports offer almost limitless connection options. Two front fans ensure reliable cooling.

The wall-mountable BoxedLine series is related to the 19-inch CL classics, can be flexibly attached to the mounting plate in the control cabinet and has a more compact design overall, just like a box. As with the 19-inch industrial PCs, the focus here is on ample connectivity, degrees of freedom in expansion and high performance. Inside the computer unit, the motherboard is responsible for this, ensuring that the components of the computer are connected and can work together.

Good to know for the experts in purchasing: one can equip the new motherboards with less expensive Pentium and Celeron units or with Xeon CPU (Central Processing Unit) for server operation. This clearly shows: the computer performance can be scaled almost freely for the application and one keeps an eye on the costs.

Human interface

Embedded PCs are more compact. Distinctive features are the particularly small housing, the mostly fanless cooling concept and the external power supply. "The embedded PCs can be integrated, for example, as an IoT gateway in smart factory applications or as a communication module in driverless transport systems in intelligent logistics," the industrial PC expert describes the field of application. The harsh environments are decisive for the resistance of the embedded PCs. The minimal power requirement - a maximum of 25 watts - is astonishing. Embedded PCs can also be supplied with WLAN, 3G and special mounting sets for mobile applications.

In the case of 19-inch, embedded or wall-mounted IPCs, the main distinction is between the "inner values". The panel PC is the direct interface between man and machine and combines modern display technology with computing power. The focus is thus also on operation and the installation situation. "For example, there are specially developed panel PCs for the food industry. In the stainless steel housing with smooth surfaces, they are IP65 or IP67K protected all around and can be cleaned hygienically with the steam jet unit," explains Götz. In addition to the computer features, the display attributes such as diagonal dimensions, resolution, contrast ratio and usability, e.g. via projected capacitive multi-touch screens, are also coming into focus. Added to this is the variety of installation options: whether open frame for direct integration from the rear, panel mount for installation from the front, 19-inch rack mount for the existing 19-inch frame or installation via the VESA interface on the rear of the panel PC.

Service logistics

Service logistics

To ensure that industrial PCs always work quickly and effectively in the long term in Integrated Manufacturing, special attention is paid to long-term availability and service logistics. "We know from experience about the importance of service competence and integration into the value-added processes of the customers and those of the end users," explains Götz. As a concrete example, he cites the firmly defined maintenance cycles in automobile production. Industrial PCs are continuously replaced and checked to ensure plant availability. After maintenance has been completed and quality tests have been successfully completed, the systems are reintegrated into the production process.

-> To the industrial PC products

-> To the original article of "Beschaffung aktuell" (German)